In an era where environmental sustainability and food safety are global priorities, fluorine-free biomass oil-proof paper has emerged as a revolutionary alternative to traditional fluorinated oil-proof materials. Designed to eliminate the risks of per- and polyfluoroalkyl substances (PFAS) while leveraging renewable resources, this advanced packaging solution redefines performance, safety, and environmental responsibility. Below is an in-depth exploration of its core components, manufacturing technologies, performance metrics, sustainability credentials, and industry applications.

Fluorine-free biomass oil-proof paper is a food-contact packaging material engineered to repel oil, grease, and moisture without relying on fluorine-containing compounds—including PFAS, often referred to as “forever chemicals” due to their bioaccumulative and persistent nature in the environment and human bodies. Its defining characteristic is the use of biomass-derived materials as primary raw materials or functional additives, sourced from renewable, natural resources that minimize ecological impact.

Plant-based polymers: Cellulose (extracted from wood pulp, sugarcane bagasse, or wheat straw), hemicellulose, and lignin—abundant in agricultural and forestry by-products, ensuring a circular supply chain.

Biological macromolecules: Chitosan (derived from crustacean shells), starch (from corn, potato, or tapioca), and pectin (from fruit peels)—all GRAS (Generally Recognized as Safe) certified, with inherent biodegradability.

Advanced bio-based additives: TEMPO-oxidized nanocellulose (enhancing barrier properties at the nano-scale), hyaluronic acid (improving film flexibility), and plant-derived waxes (such as carnauba wax or beeswax, boosting oil resistance).

These materials replace synthetic fluorinated coatings and plastic laminates, ensuring the paper is non-toxic, free of harmful migrations, and aligned with global food safety standards.

Unlike traditional oil-proof paper, which relies on PFAS-based coatings to repel oil, fluorine-free biomass oil-proof paper uses biomimetic and green processing technologies to create a physical or chemical barrier against grease penetration. Core manufacturing processes include:

Raw biomass materials (e.g., cellulose, chitosan) are dissolved or dispersed in water to form a uniform slurry. Additives like nanocellulose or plant waxes are integrated to enhance density and repellency.

The slurry is coated onto base paper (typically kraft paper or recycled paper) via precision processes such as curtain coating, roll coating, or spray coating.

The coated paper undergoes low-temperature drying (to preserve biomass integrity) and curing, allowing the biomass components to self-assemble into a dense, continuous barrier layer. This layer physically blocks oil molecules from penetrating the paper fibers.

Technologies like plasma treatment or enzymatic modification are used to alter the surface properties of the base paper, increasing its affinity for biomass coatings and improving adhesion.

For high-performance applications, a dual-layer coating is applied: an inner layer (cellulose-starch blend) for moisture resistance and an outer layer (chitosan-nanocellulose composite) for oil repellency.

Some manufacturers adopt the FluoZero™ process (a proprietary green technology) to create a nano-porous structure on the paper surface, where biomass molecules form a “labyrinth” that slows and blocks oil diffusion.

Cross-linking agents (derived from plant extracts like tannins) are added to strengthen the barrier layer, improving its resistance to high temperatures and mechanical stress.

All manufacturing processes prioritize water-based formulations, avoiding volatile organic compounds (VOCs) and toxic solvents, making the production cycle environmentally benign.

Fluorine-free biomass oil-proof paper is not just an eco-friendly alternative—it delivers performance that meets or exceeds industry standards for oil resistance, temperature tolerance, and usability:

Rated using the KIT test (ISO 16535), the gold standard for Food Packaging oil resistance. Most products achieve KIT Level 6–8 (resisting pure soybean oil for 24 hours), while high-performance grades reach Level 10–12 (withstanding heavy grease from fried foods like french fries or chicken wings for 48+ hours).

Resists a wide range of oils, including vegetable oil, animal fat, and mineral oil, making it suitable for diverse food applications.

Operates in a broad temperature range: from -34°C (for frozen food packaging, such as pizza boxes or ice cream wrappers) to 220°C (for high-temperature applications like microwaveable meals or oven-baked goods).

Maintains structural integrity and oil resistance even after exposure to hot oil (85°C) for 30 minutes or freezing (-20°C) for 30 days, outperforming many plastic-laminated papers.

Tear resistance and tensile strength are comparable to traditional kraft paper, ensuring durability during packaging, transportation, and use.

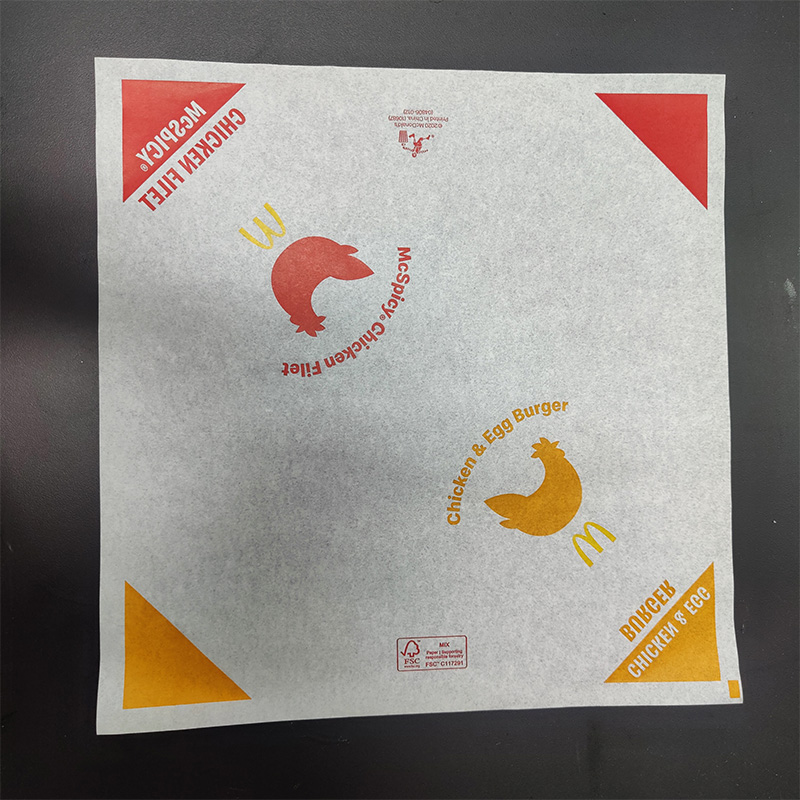

Printable with water-based inks, allowing for brand customization (logos, product information) without compromising oil resistance or safety.

Breathable (unlike plastic packaging), preventing moisture buildup and preserving the freshness of baked goods, sandwiches, and fried foods.

Meets strict global regulations: FDA (U.S.), EFSA (EU), GB 4806 (China), and REACH (EU) standards for food contact materials.

Zero PFAS, heavy metals, or toxic additives—no risk of harmful substance migration into food, even under high-temperature or acidic conditions (e.g., citrus-based foods or vinegar-containing dishes).

A key advantage of fluorine-free biomass oil-proof paper is its full-life-cycle environmental sustainability, addressing the three pillars of sustainability:

Biomass raw materials are derived from agricultural/forestry by-products (e.g., sugarcane bagasse, wheat straw) or fast-growing plants (e.g., bamboo), reducing reliance on non-renewable resources like petroleum (used in plastic packaging) or virgin wood pulp (used in some traditional papers).

Many manufacturers source raw materials from certified sustainable farms, ensuring responsible land use and biodiversity protection.

Production requires 30–50% less energy than plastic-laminated paper or fluorinated paper, as biomass coatings are water-based and require low-temperature drying.

Carbon emissions during manufacturing are offset by the carbon sequestration of biomass feedstocks (plants absorb CO₂ during growth), resulting in a near-net-zero carbon footprint.

Compostable: Breaks down into organic matter (humus) in industrial or home composting environments within 90–180 days, leaving no toxic residues.

Recyclable: Non-laminated design allows it to be recycled with standard paper waste, reducing landfill waste.

Biodegradable: Even if disposed of in landfills, it decomposes naturally over time, unlike plastic or fluorinated paper, which can persist for centuries.

By contrast, traditional fluorinated oil-proof paper releases PFAS into soil and water during disposal, while plastic-laminated paper is difficult to recycle and contributes to microplastic pollution.

Fluorine-free biomass oil-proof paper’s combination of safety, performance, and sustainability makes it suitable for a wide range of applications, spanning food packaging and beyond:

Fast Food & Takeout: Hamburger wrappers, fried chicken boxes, french fry sleeves, pizza boxes, and sandwich wraps—ideal for greasy or high-temperature foods.

Baked Goods: Cake boxes, cookie bags, bread wrappers, and pastry boxes—preserves freshness while resisting oil from butter, margarine, or chocolate.

Frozen Foods: Pizza boxes, frozen meal containers, and ice cream wrappers—withstands freezing temperatures without losing oil resistance.

Specialty Foods: Snack packaging (potato chips, nuts), deli meat wraps, and airline meal boxes—complies with strict safety standards for commercial food service.

Cosmetics & Personal Care: Hair dye palettes, nail polish remover pads, and skincare product packaging—resists oil-based ingredients and chemicals.

Industrial Packaging: Wrapping for mechanical parts (to prevent oil stains) or electronics (to repel moisture and grease).

Household Products: Disposable oil-absorbing sheets, microwave popcorn bags, and food preparation mats.

Fluorine-free biomass oil-proof paper represents a paradigm shift in packaging—proving that environmental responsibility, food safety, and performance can coexist. By leveraging renewable biomass resources, green manufacturing processes, and full-life-cycle sustainability, it addresses the critical flaws of traditional materials while meeting the evolving needs of brands, regulators, and consumers. Whether for fast food chains, bakeries, or industrial suppliers, this innovative paper is not just a packaging solution—it’s a commitment to a healthier planet and safer food supply.